Description

The HYDRO 1V-2V-3V series multicellular electro-pumps are used to transfer clean water, without additives, which could damage the materials of the equipment,

They are made up of VIP VT vertical multistage pumps with stainless steel impellers (AISI 304) and a control panel, which automatically starts and stops, ensuring the correct operation of the installation.

Equipment for pressurized water distribution in large installations, residential buildings, commercial premises, industries, or any type of installation that requires a constant water pressure, an autonomous installation with low maintenance and silent.

The most important features are :

- Compact and ready-to-install stand-alone pumping unit

- Pressure regulation by means of pressure switches and membrane or galvanized accumulators.

- Electrical power and control panel, with metal support, for fully automatic operation

- In standard configuration they are manufactured with 1 two or three pumps, which start alternately and in cascade as the pressure drops and the pressure switches are activated.

- Silent pressure equipment.

- Modular manufacture configurable according to the required equipment with the outputs ready to tackle the network and the accumulation equipment.

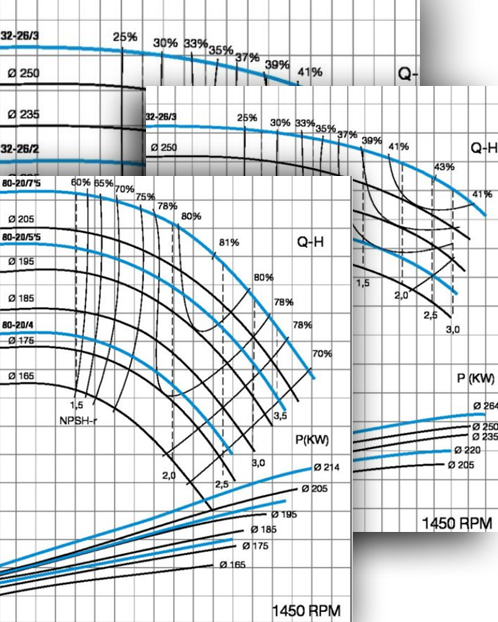

- The appropriate HYDRO 1V-2V-3V equipment is defined in the selection table, depending on the required flow rate and head.

- The power range is from 1x 1,1 to 3x 5,5 Kw, from flow 0,9 to 90 m3/h and from height 2 to 120 m.c.a.

- Maximum liquid temperature 50ºC

- The accumulator tank is available on request

- Also available in Hidrovar frequency. Hydrovar with rotameter and Multimaster.

- Drinking water networks

- Pressure Washing

- Sports facilities

- Hotels

- Pressure Equipment for Houses

- Urbanizations

- Toilet rooms in shops, markets and shopping centres.

- Water distribution from a tank

- Water distribution from a tank

- Small hydraulic applications

- Factories

- Laboratories

Depending on the needs of the installation itself, contemplated in the project, can be distinguished different configurations formed by:

- 1 / 2 / 3 VIP V Three-phase . With threaded suction and discharge flanges, radial type steel impellers (AISI 304), graphite/ceramic mechanical seal, suction and discharge body in GG-25, diffusers in glass fibre reinforced noryl, in monobloc configuration and stainless steel shaft motor.

- Pressure gauge up to 16 Bar: The pressure gauges are used to see the pressure of the water, inside the pipe in an installation, is capable of withstanding a maximum pressure of 16 bar.

- Pressure switch 3-12 BAR : The pressure switch is perfect for the pressures that the pressure equipment will handle, it closes when the pressure drops and opens when the pressure rises.

- Bench . Steel base, common for pump and electrical panel.

- Impulse manifold. It is the element that joins all the elements, by means of valves, allows the union of all the elements that form the equipment.

- Shut-off valve. In the drive, mat type

- Non-return valve. To avoid returns and water hammering

- Multifunction electrical panel EMC: For 1 or more pumps, with:

- Power failure

- General disconnector and door lock

- Control of macha/stop.

- Manual start button

- 0-aut button (alarm reset)

- Electronic wiring fault detection

- Safety to avoid restarts and sudden stops caused by water hammer.

- Water level protection to prevent dry running.

- Air loss fault

- Pressure failure

- Manual start button

Pressure Equipment with Vertical Multicellular Electric Pumps

HYDRO 1V-2V-3V Series

MANUAL

Call us

Send us an Email