Description

EBAR prefabricated pumping stations are fully automated equipment, specially designed for pumping wastewater either main pumping stations, or intermediate, managing wastewater, mainly in places where it is not possible or economical drainage by gravity.

Eliminate unwanted odour problems due to sulphide build-up in wastewater.

Due to their high resistance, they can be buried

- EBAR pumping stations are built in PVRF with inlet and outlet piping, cable outlet and ventilation.

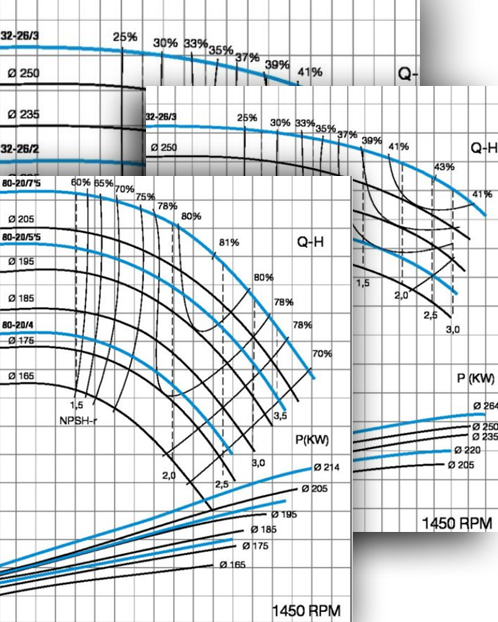

- Installation of two submerged sewage pumps, ARS series, for flows between 10 and 600 m3/h, with impellers, grinders, drainage, vortex, single-channel open, single-channel or multi-channel (according to needs) and quick coupling systems and guide tubes.

- Stainless steel chains for pump insertion.

- Its working capacity can be configured according to needs, either in useful volume or in impulse power.

- Level switches, for function control

- Bulkheads for pump and signal cables.

- Check and shut-off valves

- Access rag (man’s mouth) with anti-fall bars.

- Access ladder to the pumps.

- Ventilation outlet

- Health centres

- Service Areas

- Shopping or sports centres

- Pumping wastewater, rainwater, or sewerage

- Municipal and industrial facilities

- Railway stations

- Urbanizations of houses

- Zootechnical farms

- Impeller : GG25

- Engine housing : GG-25

- Stainless steel shaft : AISI-420

- O-rings : Nitrile

- Stainless steel screws. AISI-316

- Maintenance-free, permanently lubricated bearings

- Mechanical seals : Silicon carbide/silicon

- Electric cable : Neoprene H07RB/7

- High efficiency three-phase electric motor, squirrel cage type, IP68 protection, insulation class F and H

- Stainless steel plate : AISI-304

- Stainless steel suction chimney : AISI-304

- Stainless steel channels : AISI-304

Optionally, it can be used in special steels, especially when the fluid contains abrasive material.

Call us

Send us an email