Description

- Its modular composition is formed by the hydraulic pump, and the submersible electric motor, which is coupled to the bottom of the pump.

- They can work vertically or horizontally (with cooling bell).

- The pump is supported by the tubes of columna´, which expel the water to the outside.

- Custom fabrication for every application and installation.

- Maximum liquid temperature 25º.

- Maximum sand 40 gr/m3

Some of its advantages are :

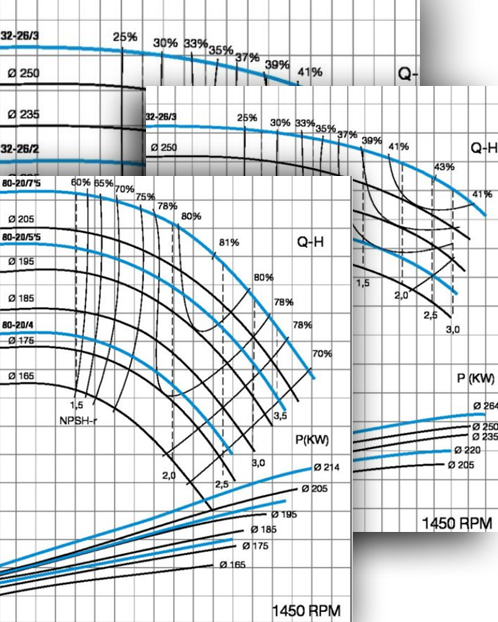

- Good hydraulic performance, higher yields

- Its configuration allows to increase/decrease the pressure, adding or eliminating phases.

- Eliminates priming complications, pump always in charge (submerged)

- Eliminates problems in aspiration

- Avoids air intakes

- No pump-motor alignment problems

- Less noise pollution

- Cost reduction, minimum maintenance.

- No need for a bench, reduced installation space

- Less civil works

- Longer service life

The installations of the series consist of three parts:

1- Hydraulic body

- The hydraulic body is made up of a suction body, a discharge body, and stages or phases, made up of diffuser bodies and closed multi-channel impellers of the semi-axial type.

- The diameter of the group can be 6-8-10-12-14 and 16 inches, it varies according to the perforation and the service data.

- The operating pressure can be obtained by incorporating the necessary number of stages thanks to its modular configuration.

- The set of impellers driven by the central shaft that transmits the power of the motor.

2- Submersible electric motor

- Electric submersible motor of 50 or 60 Hz with IP-68 protection that supports the axial thrust of the pump, by means of a widely dimensioned axial bearing.

- The stator winding is flooded in oil or water, depending on whether it is 6-8-10 and 12″, in all cases the bearings are lubricated by the internal liquid, and do not need maintenance.

- These engines are manufactured by the most prestigious specialized firms.

- The coupling flanges are designed in accordance with NEMA standards, simplifying maintenance and repair operations.

3- Hydraulic column

- The hydraulic column is made up of sections, depending on the depth of the well. These sections consist of tubes with steel flanges.

SD pumps are suitable for:

- Water supply and distribution.

- Overpressure systems

- Water treatment sewage treatment plants

- Irrigation and sprinkler installations

- Mines

- Waterparks

- Cooling towers

- Chemical industries

- Conventional or nuclear thermal power stations.

- Refineries, pumping of crude and refined products

- Sanitary and cleaning facilities.

- Industry in general

1- Hydraulic Body

- Suction body: GG25 – (Optional bronze, superduplex, AISI, steel)

- Drive body: GG25 – (Optional bronze; superduplex; AISI; steel)

- Diffuser body: GG25 – (Optional bronze, superduplex, AISI, steel)

- Rodete: GG25 – (Optional bronze, superduplex, AISI, steel)

- Pump shaft: AISI 420 (Optional AISI 316)

- Bushing: AISI 1045 – (Optional AISI 316)

- Casting: stainless steel

2- Hydraulic Column

3- Motores

- IP68 submersible motors in water or oil bath. (Optional AISI 316)

Multicellular submerged centrifugal electric pumps for deep wells

MANUAL

CATALOGUE OF PRUDUCTO SUM 1078

Call us

Send us an Email